Anping Yuanqiao Petrochemical Equipment Co., Ltd, founded in 2000, covering an area of 50000 square meters, is

located in Anping County, Hebei Province, known as the "hometown of

Chinese silk screen" and "silk screen industrial base". It is a

professional manufacturer of wire mesh demister, vapor liquid

filter screen, and steel plate mesh. It is committed to providing

reliable quality separation devices for the manufacturing industry,

and has the qualification of general taxpayer and independent

import and export rights.

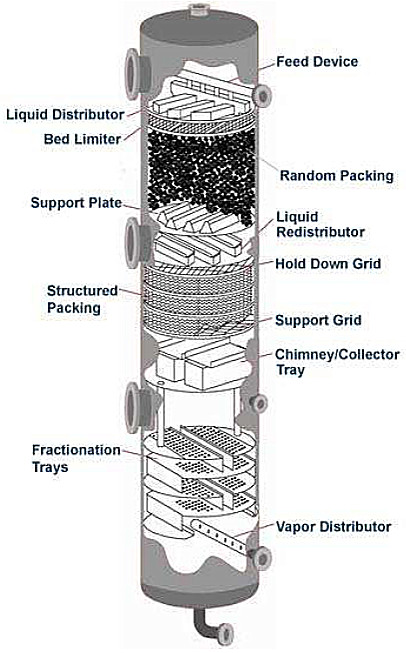

The main products of the wire mesh demister series include metal

wire mesh demister, plastic wire mesh demister, pp wire mesh

demister, drawer type wire mesh demister, embedded wire mesh

demister, top mounted wire mesh demister, and bottom mounted wire

mesh demister. Wave type wire mesh demister, also known as wave

type demister or waveform demister. In industrial production, the

removal of various mist, mist, vapor liquid separation, and

particle separation in the air can achieve a capture efficiency of

98% -99.8% for mist with a particle size of ≥ 3~5um. It is widely

used in gas-liquid separation devices in industries such as

chemical, petroleum, tower manufacturing, and pressure vessels for

desulfurization, mist removal, water removal, and droplet recovery

in environmental engineering.

We are a physical manufacturer specializing in the production of

vapor liquid filter screens and their products. Our company mainly

produces metal vapor liquid filter screens in three types:

stainless steel, copper, brass, alloy, and pure metal. Among the

stainless steel materials, 304, 304L, 321, 316, and 316L are widely

used, with Monel alloy as the main alloy material and pure nickel

and titanium as the main pure metals. Our company mainly produces a

series of products with over a hundred specifications and models in

four categories: standard type, high-efficiency type, high

penetration type, and damping type.

For many years, our company has established stable trade relations

with multiple merchants with high-quality products, good

reputation, and high-quality services. Our products are widely sold

throughout the country and exported to countries and regions such

as Japan, Singapore, Taiwan, etc. May we cooperate sincerely and

seek common development on the basis of mutual integrity. Warmly

welcome your visit